steel bend test procedure|tensile bend testing : exporters The tensile test procedure involves attaching the sample to the testing machine and applying force until the material fractures. The results are typically recorded in a stress-strain diagram. . ASTM A370 – Standard Test Methods and Definitions for Mechanical Testing of Steel Products; Importance of Tensile Test. . See also Bend Test in . OnlyFans Kinechan Gordinha transando de quatro gemendo. Privacy Kinechan Bucetuda pelada sensualizando gostoso. Privacy Kinechan Safada levando gozada na boca.

{plog:ftitle_list}

Porn Rule 63 pictures by your favorite characters from the mo.

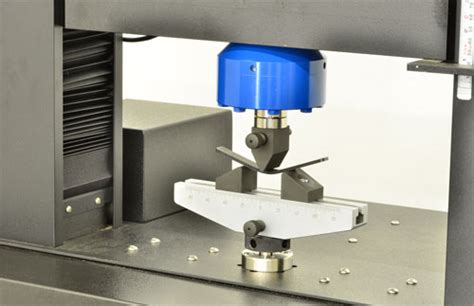

ASTM E290 A-26, ISO 7438 I-8, and JIS Z2248 J-5 are some of the general standards which describe the requirements for the bend testing of metals. In a Three-Point Bend Test, a . While it is easy to imagine why bend testing needs to be performed on rigid materials like plastics (ASTM D790) and concrete (ASTM C1609), in reality bend test applications are common in a variety .11.3.2.1 (1) Procedure. The bend test shall be made on specimens of sufficient length to ensure free bending and with apparatus which provides: a) Continuous and uniform application for force throughout the duration of the . Chapter 11 Standard Test Procedures Steel Reinforcement Tests MAY 2001 Page 11.15. Title: N-Stand Test-Chapter-11a.PDF .The bending test procedure when using the 1-point bending device is as follows: The specimen is clamped at one end and its exposed side is loaded with the test punch. Following, the flexural modulus is calculated. A flexural .

The tensile test procedure involves attaching the sample to the testing machine and applying force until the material fractures. The results are typically recorded in a stress-strain diagram. . ASTM A370 – Standard Test Methods and Definitions for Mechanical Testing of Steel Products; Importance of Tensile Test. . See also Bend Test in . B1. Longitudinal Guided-Bend Test (See Part A1, section 7.6, Fillet Weld Root Bend Test.) 1. Scope 1.1 This section covers the bend testing of fillet welds. The standard gives the requirements for guided bend test specimen preparation, test parameters and testing proce-dures, but does not specify the requirements or accep-tance criteria.

3.3 While the bending equipment used in many of the methods is generically the same, there may be differences in bending procedures, material allowances, hold and pull legs, wall thickness, etc., between bending fabricators. 3.4 Hot bending methods 3.4.1 FURNACE BENDING: In this method, the pipe is firmly packedMechanical test methods that are applicable to welds and welded joints are described. For each testing method, informa- . procedure to be followed, and report requirements are also described. ISBN: 978-0-87171-889-1 . bend tests, fracture toughness tests, hardness tests, break tests (nick and fillet welds),Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is .section of side 40 mm. The bar was placed on the bending support at the minimum span and load–displacement curves were obtained. The displacement rate was 1.4 mm/min and the maximum load was approximately 7000N”[1]. Fig. 2 shows the testing configuration. Fig. 1. Load-displacement curve of an indentation test . Fig. 2. Example of .

The weld should not fail and the metal should not crack under the stress during bending for an acceptable bend test result. What is the Bend Test in welds, & the Types of Bend Test? The bend test is specified in ASME section 9 and AWS D1.1 for welder testing & weld testing for performance & procedure qualification. 3. As stated previously, radiographic testing may be used in lieu of bend tests. Procedures, technique and acceptance criteria for this type of test is provided in Clause 8 (Inspection) of AWS D1.1/D1.1M:2020 Structural Welding Code – Steel (Clause 6 if you are still using the 2015 edition).Steel reinforcing bar, or rebar, is embedded in concrete to . typically fall into the following basic test categories: Tensile Bend Compression Fatigue Other related product testing, such as slip testing of . Testing procedures or methods Calculations or results to be determined Starting to bend the second root bend coupon. Half way through the bend test. Almost done with the bend test. This root bend looks good so far. This was a nail biting moment. The Certified Welding Instructor/Inspector took the first root bend coupon that had the opening in it and put it under a magnifying glass.

Detech.co.id – Pengertian Uji tekuk (bending test) merupakan salah satu bentuk pengujian untuk menentukan mutu suatu material secara visual. Proses pembebanan menggunakan mandrel atau pendorong yang dimensinya telah ditentukan untuk memaksa bagian tengah bahan uji atau spesimen tertekuk diantara dua penyangga yang dipisahkan oleh jarak .

what is bend testing

tensile bend testing

This article discusses the different bend tests with emphasis on test methods, apparatuses, procedures, specimen preparation, and interpretation and reporting of results. The types of bend tests discussed are bending ductility tests, bending strength tests (ASTM E 855), bend tests as per EN 12384 and JIS 3130, and computer-aided bending tests .It tests the ability of unreinforced concrete beam or slab to withstand failure in bending. The results of flexural test on concrete expressed as a modulus of rupture which denotes as (MR) in MPa or psi. The flexural test on concrete .

The bending test of TMT bars is performed to test the steel ductility without affecting the steel strength. Conversely, the re-bend test is used to measure the effects of strain aging on steel. In steel, embrittlement can .

The procedure below uses the MTS C64.206 test machine along with a pre-programmed test procedure. The pre -programmed test procedure should be adequate for most re inforcing bar testing. . aids are small, stainless steel “L” shaped pieces that mount to the grips using two screws. With the grips placed on a table, place the specimen in the . The test procedure, as well as the test tubes used for bend testing of the butt welded joints, are defined by the Standard EN 910 (Welded butt joints in metallic materials-Bend test) [3].The T-bend test is used to assess coating formability and adhesion. The highest rating, '0T', corresponds to a 180 • bend of the steel, resulting in the highest potential surface strain [42 .

8 Procedure. 9 Interpretation of results. 10 Test report. . European Committee for Iron and Steel Standardization, . Cheong K. et al., ?Evaluation of the VDA 238-100 Tight Radius Bending Test using Digital Image Correlation Strain Measurement?, Int. Journal of Physics, . UTM, test specimen, bending table support pin. Procedure: Take a test specimen of the steel rod. Measure the diameter of the steel rod. Take at least 3 readings and calculate the mean. Now place the test specimen in the bending table specimen should be kept in the bending table in such a way that the planeSteel bars for reinforcement of concrete - Bend and rebend tests Barres en acier pour beton arm6 -- Essais de pliage-dkpliage Reference number . 6 Procedure 6.1 Bend test 6.1.1 The test shall be performed at a temperature between 10 “C and 35 “C. 6.1.2 The test piece shall be bent over a .

Small-scale bending tests (Fig. 7) provide a simply fixable set-up for anchors characterization in combined shear-bending and even in equilibrium critical application.It is probably the closest combination of stresses to simulate a real-scale bended structure, which is possible through a small-scale test [97].In this case, recovery of characterization data from the .An unproved machine for making the bend test is described The bend is made in this apparatus in a theoretically correct manner It 18 adapted to use in any universal or compression testing machine The significance of the bend test is discussed and data are submitted showing the relation of size of bar, shape of bar and angle of bend to The welder qualification test coupon or WQT as stated above needs to meet the weld soundness and that is verified either by performing a volumetric NDT test (such as radiographic testing or Ultrasonic testing) or by destructive testing such as bend test. Visual testing is mandatory but it is only for surface inspection.

The four-point flexural test provides values for the modulus of elasticity in bending, flexural stress, flexural strain and the flexural stress-strain response of the material. This test is very similar to the three-point bending flexural test.The major difference being that with the addition of a fourth bearing the portion of the beam between the two loading points is put under maximum .

standard bend testing methods

1993 evinrude 175 hp compression test

Read and download 27 hentai manga, doujin or comic porn with the artist adsouto free on HentaiZap.

steel bend test procedure|tensile bend testing